Manufacturing Solutions

Optra Edge offers numerous benefits to the manufacturing industry, revolutionizing the way operations are managed and executed. By deploying computational power and data collection closer to the production line, edge computing enables real-time data analysis and decision-making. This allows manufacturers to optimize their processes, enhance worker efficiency, and reduce production downtime.

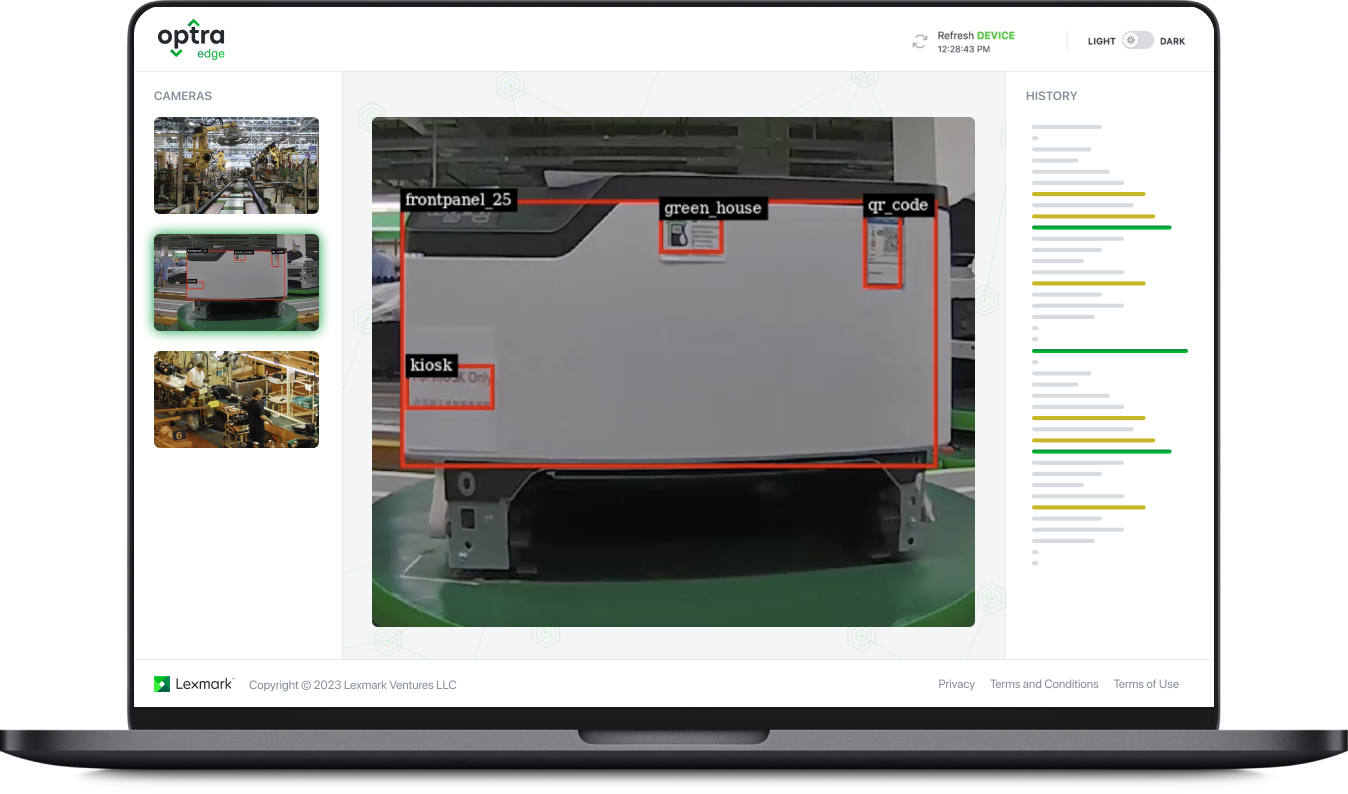

With Optra Edge, cameras and sensors on the factory floor can collect and process vast amounts of data, generating valuable insights instantly. This empowers manufacturers to monitor processes, predict maintenance needs, and prevent costly breakdowns. Furthermore, edge computing facilitates localized data processing, eliminating the need for large-scale data transfers to the cloud, reducing latency, and ensuring uninterrupted operations. Manufacturers can also leverage edge computing for quality control by instantly analyzing data from sensors, cameras, and machine vision systems, leading to improved product consistency and reduced waste.

Overall, Optra Edge empowers the manufacturing sector with faster, more reliable, and intelligent decision-making, paving the way for increased productivity, cost savings, and enhanced competitiveness.

Devices

4Skills

1Actions

1Optra Edge Benefits for Manufacturing

Improved quality control

Optra Edge enables manufacturers to analyze data from sensors, cameras, and machine vision systems in real-time. This allows for immediate quality control checks, ensuring consistency and detecting defects early in the production process, leading to higher product quality and reduced waste.

Real-time monitoring and predictive maintenance

Edge computing allows manufacturers to monitor equipment and machines in real-time, analyzing data on-site to detect anomalies and predict maintenance needs. This enables proactive maintenance, reducing unplanned downtime and maximizing operational efficiency.

Localized data processing

Optra Edge enables localized data processing and analysis, reducing the need for sending massive amounts of data to the cloud. This minimizes latency and ensures immediate response times, critical for time-sensitive manufacturing processes. Additionally, this localized processing can exist within highly-secure air-gapped environments.

Enhanced operational efficiency

With edge computing, manufacturers can leverage real-time analytics to optimize production processes. By analyzing data from cameras and sensors on production lines at the edge, manufacturers can identify bottlenecks, streamline workflows, and improve overall operational efficiency.

Enhanced supply chain visibility

Optra Edge facilitates real-time tracking and monitoring of inventory and assets throughout the supply chain. By collecting and analyzing data at the edge, manufacturers can gain accurate and up-to-date insights into their inventory levels and logistics operations, enabling better inventory management and reducing stockouts or excess inventory.

We’re here to help

Our Edge Computing experts are here to provide personalized consulting, custom hardware and firmware development, security consultation, remote device management and more.

Build less and do more with a library of plug and play skills

Easily create and consume software skills that can be chained together to create custom workflows unique to your business needs. Deploy them to your entire fleet instantly.

Browse Skills